Another Rostock derived Delta 3d printer with very detailed build guide.

From project page:

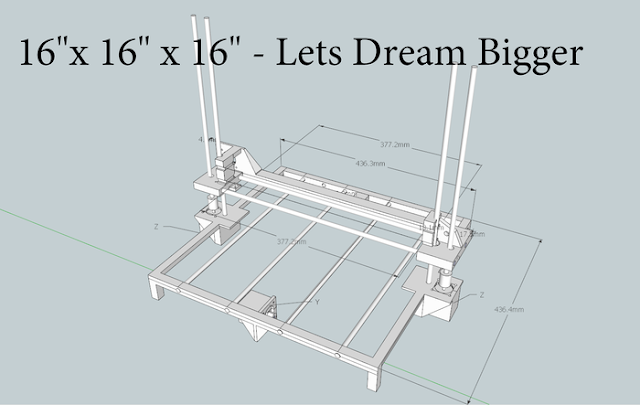

The MOST Delta printer is RepRap derived from the Rostock printer with the following design goals:The design utilizes plywood linking boards cut to a length that yields a desired printer radius when attached to the printed apexes. This simplifies assembly while helping to assure that printer dimensions are fixed, stable and reasonably well known. It also improves flexibility as the print area in the x-y plane can be changed simply by replacing the boards with boards of a different length. The delta design is inherently simpler to assemble as compared to virtually all it's Cartesian counterparts; this design can easily be built within a day by one person having properly prepared parts.

- Simple build process

- Safe to operate

- True to RepRap

- Maximize value

- Maximize rigidity

- Aesthetically pleasing (or at least neutral)

- All PLA printed parts

- Excellent print performance

The design uses a 12v 5A power brick instead of the popular 12v power supplies having mains connections relatively exposed, a relative safety issue, particularly when children are present. The power supply is roughly equivalent to those found with many inkjet printers.

As many printed parts are used in the design as are practical, including printed pulleys. This in large part drove the decision to use open T5 timing belts for the drive, which also makes the design more flexible as the length of the guide rods doesn't need to be based upon the length of an off-the-shelf continuous belt.

Cost considerations drove decisions regarding everything from printer capabilities (as shown, prints PLA only) to guide rod material and length (two six foot lengths of 8mm drill steel are required, producing no waste). A Melzi controller is used as it provides all the necessary features as well as SD card support and reasonable expansion options. The power supply is a fraction of the cost of that required for powering a heated bed.

Printed apexes are very robust, probably overkill, and along with the plywood components and ample fasteners produce a very rigid structure. The printer has proven to transport very well (and can even be seat belted) with no adjustment needed prior to printing at its destination.

The end effector is actively cooled allowing for a unitized effector/hot end mount printed in PLA. The hot end is recessed within the end effector, maximizing z-axis travel and also providing for some print cooling.

Printing performance has been very good as has been the experience of printing with this design. Much less user intervention has been required as compared to experience with Cartesian RepRaps.

Printer capabilities/statistics

- Print media: PLA only (heated bed can be added, expanding media options)

- Filament diameter: 1.75mm

- Nozzle diameter: 0.5mm (can be changed)

- Print volume: ~250mm radius (with 240mm long linking boards) 270mm high

- Melzi print controller w/ integrated SD card reader

- Airtripper's Bowden Extruder

Appropedia page with very detailed build guide:

http://www.appropedia.org/Delta_Build_Overview:MOST

Github file repository:

https://github.com/mtu-most/most-delta

Appropedia is very interesting wiki with many detailed open source DIY projects woth looking at.

Appropedia is the site for collaborative solutions in sustainability, poverty reduction and international development through the use of sound principles and appropriate technology and the sharing of wisdom and project information.

I'll post about more interesting Appropedia projects soon.

It can also be stacked in a tower configuration as someone successfully did here with 4 deltas stacked:

MOST is Pearce Research Group at Michigan Tech in Open Sustainability Technology.

They have many cool stuff here: http://www.appropedia.org/MOST