From video description:

MakerBot CEO Bre Pettis introduces the fifth generation MakerBot Replicator Desktop 3D Printer, now available at http://www.makerbot.com/replicator

Today, we're excited to announce the latest addition to the MakerBot 3D Ecosystem. Introducing the all-new fifth-generation MakerBot Replicator Desktop 3D Printer! Built from the ground up, the MakerBot Replicator Desktop 3D Printer defines a new standard in reliability, quality, and ease of use.

All fifth-generation MakerBot 3D Printers are powered by the MakerBot Replicator 3D Printing Platform, which offers amazing features like:

• A groundbreaking user interface equipped with a 3.5" full-color LCD display

• An on-board camera for remote print monitoring and easy sharing

• The easily swappable and replaceable MakerBot Replicator Smart Extruder, which detects filament absence and automatically pauses your print

• An assisted leveling system to make leveling your build plate easier than ever

The MakerBot Replicator Desktop 3D Printer is powerful enough for professionals, affordable enough for everyone, and completely integrated with the ever-expanding MakerBot 3D Ecosystem. We can't wait to see what you make!

It is priced at 2899 USD.

They alos announced Replicators big brother: the Replicator Z18 large volume 3d printer

http://diy3dprinting.blogspot.com/2014/01/makerbot-replicator-z18-large-volume-3d.htmland smaller version: the Replicator Mini:

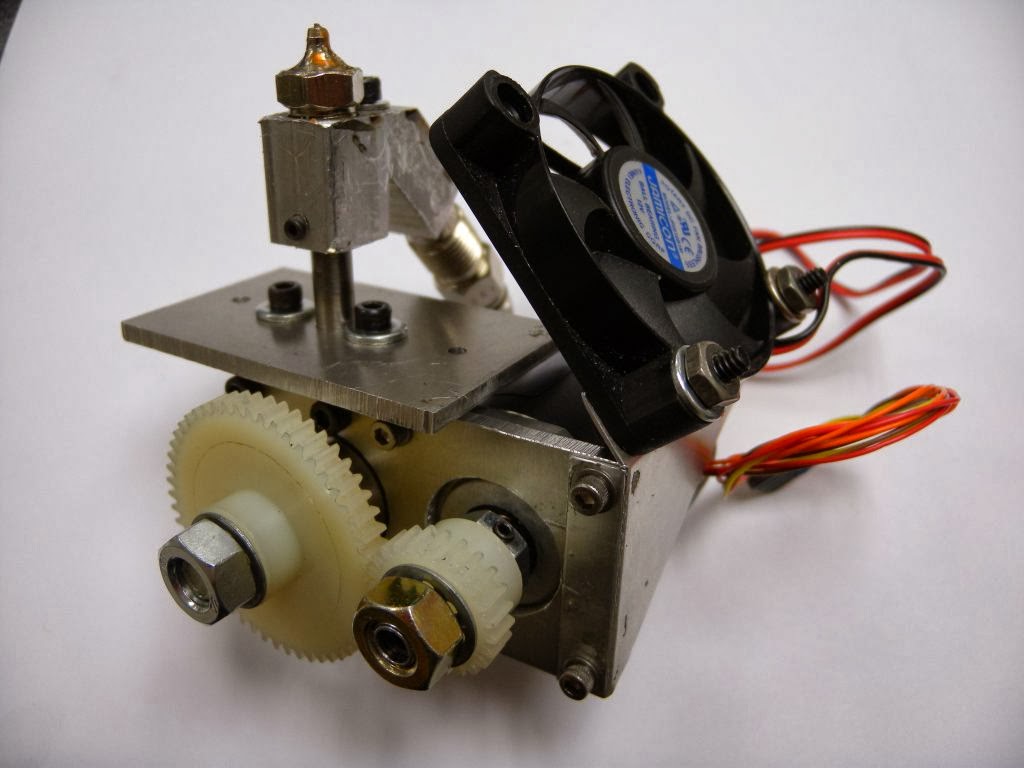

http://diy3dprinting.blogspot.com/2014/01/makerbot-replicator-mini-3d-printer.htmlThis Makerbot Replicator Smart Extruder looks interesting. It's features are:

- Easy to swap or replace

- Detects filament absence and automatically

- pauses your print

- Sends notifications to MakerBot Desktop and

- MakerBot Mobile apps

Picture of fifth generation Replicator:

Technical specifications:

TECHNICAL SPECIFICATIONS

PRINTING

PRINT TECHNOLOGY

FUSED DEPOSITION MODELING

BUILD VOLUME

25.2 L X 19.9 W X 15.0 H CM

[9.9 X 7.8 X 5.9 IN]

7,522 CUBIC CENTIMETERS

[456 CUBIC INCHES]

LAYER RESOLUTION

100 MICRONS [0.0039 IN]

FILAMENT DIAMETER

1.75 MM [0.069 IN]

FILAMENT COMPATIBILITY

MAKERBOT PLA FILAMENT

LARGE SPOOL

.9 KG [2.0 LB]

NOZZLE DIAMETER

0.4 MM [0.015 IN]

DIMENSIONS

PRODUCT DIMENSIONS

52.8 L X 44.1 W X 41.0 H CM

[20.8 L X 17.4 W X 16.2 H IN]

PRODUCT WEIGHT

~16 KG [~35 LBS]

SHIPPING WEIGHT

(INCLUDES ACCESSORY KIT) ~18 KG [~39 LBS ]

MECHANICAL

BUILD PLATFORM

GLASS

SOFTWARE

SUPPORTED FILE TYPES

STL, OBJ, THING, MAKERBOT

OPERATING SYSTEMS

WINDOWS (7+)

MAC OS X (10.7+)

LINUX (UBUNTU 12.04+)

CONNECTIVITY

USB AND ETHERNET

(WI-FI COMING SOON)

ELECTRICAL

POWER REQUIREMENTS

100–240V, 50–60 HZ

~1.75A MAX, 150W

.png)

.png)

.png)

.png)

.png)

.png)