↧

BBC report on Foodini food 3d printer by Natural Machines

↧

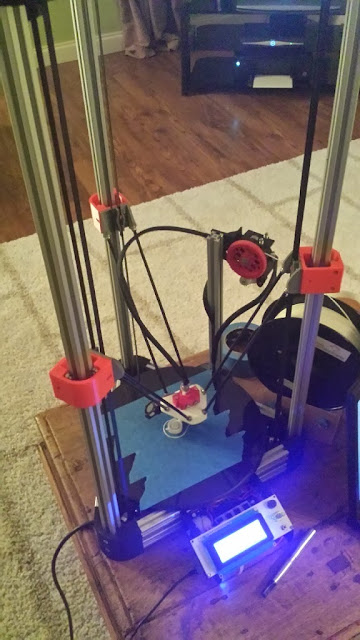

Cherry Pi Delta DIY 3D Printer by AndyCart

Deltas are everywhere ... here is new one by AndyCart ...

From Thingiverse description:

http://www.thingiverse.com/thing:210028

From Thingiverse description:

This is my own variant of a variety of 3D printer designs available. I have used ideas from Kossel, Delta Pi, 3DR and, of course, Rostock. Many thanks to the designers of those machines for their brilliant ideas that I have shamelessly 'Cherry Picked' hence the name of my design!

The rods on my printer are 277mm from steel ball centre to centre. The towers are 800mm Bosch/Rexroth aluminium extrusion and the base frame extrusions are 250mm long as are, obviously, the top frame extrusions. You need nine in all.

The bearing carriers use 6 623 10mm x 4mm x 3mm bearings and slide directly on the extrusion. Nut traps for M3 nuts are included in the carrier. The rods connect to the carrier with a plate that fastens with 3 M3 bolts, again nut traps are included. The rod carriers and the effector plate hold 10mm x 5mm countersunk, cylindrical rare earth magnets and my rod end balls are 8mm diameter. My rods are 5mm carbon tube but you could use 6mm aluminium. My rod end balls have a 10mm M5 threaded rod and are the type used for the ends of gas struts, etc. the idea of the seperate rod carriers was to enable different rod attachment methods but the magnets and balls have worked out fine for me.

http://www.thingiverse.com/thing:210028

↧

↧

ShapeDo - community driven 3d model design and collaboration

ShapeDo is new community driven 3d model design and collaboration website. It has some powerful and interesting features.

Video of collaboration features inside ShapeDo:

http://www.shapedo.com/

Video of collaboration features inside ShapeDo:

http://www.shapedo.com/

↧

Update from HYREL 3D

From video description:

Just in time for the 2013 Holidays, HYREL 3D changes the economics of 3D printing with a single, affordable machine.

Whether one of HYREL's Engines or Systems, all are able to fabricate multiple parts simultaneously.

What this means to you:

If it currently takes four hours for your 3D printer to print / fabricate a single part and you need four of the same parts, it will take at least 16 hours total with a single machine.

With a single HYREL Engine or System, your capacity to fabricate parts simultaneously on the same machine opens up the bottleneck, saves you time and valuable shop space.

So, if you need two, three, or four fabricated parts... or if you need a small production run of parts...

... or if you'd like to mix in other materials with our different extruder heads -- you can do it all on your HYREL.

Other Materials include:

Sugru, Clay, Porcelain, Precious Metal Clay (PMC), Silicone RTV, Play-Doh, Plasticines... and coming soon, Wax, Chocolate, Cheese, Peanut Butter... etc.

For the material in the video, we used four colors of ABS. Each of the Mk1 Extruders in the video have been tested and verified to fabricate parts with the following types of filament: ABS, PLA, Nylon, PET, & Rubber. More filaments are currently being tested and more will be certified as 3D printable with the Mk1s in early 2014.

http://www.hyrel3d.com/

↧

CNN video on Contour Crafting 3d printing buildings

3d printing buildings is gaining mainstream attention ... Contour Crafting Berok Khoshnevis gives interview on CNN ...

First post on Contour Crafting 3d printed houses:

http://diy3dprinting.blogspot.com/2013/11/contour-crafting-3d-printing-houses-of.html

First post on Contour Crafting 3d printed houses:

http://diy3dprinting.blogspot.com/2013/11/contour-crafting-3d-printing-houses-of.html

↧

↧

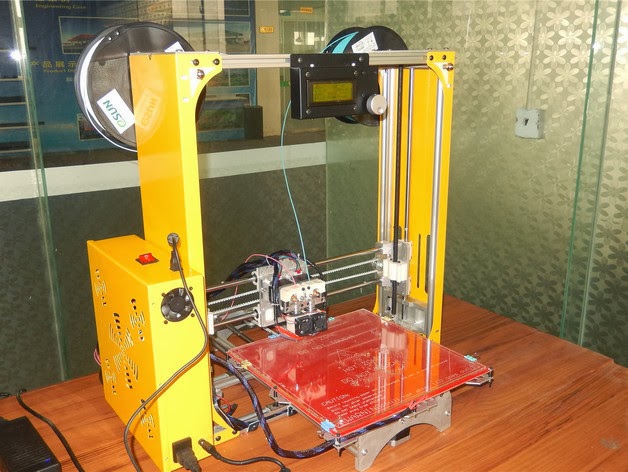

RepRap TK300 3d printer

TK300 by RockyShi is on Thingiverse now ... information may be limited, design looks sturdy, it is made with steel side plates and CNC aluminum connecting parts ...

From Thingiverse description:

Dual extruder version:

http://www.thingiverse.com/thing:212131

Base version:

http://www.thingiverse.com/thing:212115

From Thingiverse description:

- Ultimaker main board, will change to Rumba soon

- dual DD2 extruders, direct driving

- dual metal hotends E3D with cooling fans,Fast heat up

- lcd controller

- use prontface,cura or other opensource software

- 1.75mm ABS or PLA filament

- Fast change filament function

- Steel cabinet for power supply and electronics

- Borosilicate glass

- Mk2a 300mm pcb heatbed with 24v,can reach 140 centigrade

- building size 300*300*320mm

- layer thickness 0.1-0.4mm

- Steel side plates

- CNC aluminum connecting parts

- Modular packing

Dual extruder version:

http://www.thingiverse.com/thing:212131

Base version:

http://www.thingiverse.com/thing:212115

↧

PORO-LAY new family of advanced properties filaments by Kai Parthy: LAY-FELT, LAY-TEKKKS, LAY-FOMM and GEL-LAY

New 3d printing filament family by Kai Parthy the PORO-LAY. The new filament family consists of four different filaments: LAY-FELT, LAY-TEKKKS, LAY-FOMM and GEL-LAY with different properties.

From description:

From description:

PORO-LAY line (4 filaments)

dedicated for:

LAY-FELT

• 3d-membranes

• filters

• semipermeables

• future cloth

• artificial paper

soft and

stiff fibres possible

note: the filament contain no microfibres !!!

LAY-FOMM

• micro-foam,

• sponges

• ink-reservoirs

• bio-cells

• elastics...

• bendable suits

• soft rubber-like (under Shore A10), different softness possible

GEL-LAY

• objects in water

• marine organism

flow simulation

• biomechanics

muscles

high porosity,

the object is very unstable

LAY-TEKKKS

• orientated fibres

• stacked fibres

• future cloths

• tissue

↧

3d printer that prints figures in jello shots

From video description:

This is a close-up of my figures-in-jello-printing 3d-printer hack. Content of the shot glasses is jello (duh), printing fluid is a mixture of banana liquor, food colouring and starch to make it less viscose. Printer is made out of old cdrom drives

Source files:

http://spritesmods.com/jello3dprinter/jellopr.tgz

Buildlog:

http://spritesmods.com/?art=jello3dprinter

↧

Cartesio 3d printer

Cartesio is sturdy 3d printer / desktop cnc design by Jos Scheepers with aluminum frame that you can buy or build yourself. It comes in two sizes: bigger Cartesio W and smaller Cartesio M.

Cartesio W description from the project page, it is priced at 2099 euro (Cartesio M is priced at 1699 euro):

http://reprap.org/wiki/Cartesio

Project homepage:

http://www.mauk.cc/

Cartesio wiki and building instructions:

http://www.mauk.cc/service.html

You can alos find them on Thingivers under:

http://www.thingiverse.com/jos/designs

http://www.thingiverse.com/thing:21664

Cartesio W description from the project page, it is priced at 2099 euro (Cartesio M is priced at 1699 euro):

The CartesioW V0.9 has a massive build volume of 400x200x200mm and comes standard with a 3D print extruder and a large Heated buildplatform

If you want other tools (engravers, plotters,...), please select them in the Tools catagory.

The Lead time for this product is currently : 3-6 weeks after payment has been received

We can also assemble Cartesio for you.

- Cartesio is a feature rich profesional CNC router.

- It supports a wide range of tools ig. 3D-print extruder and engraver.

- It is possible to print multiple colors, or materials.

- unique features :

- quiet printing

- very rigid build platform which does not move in X,Y direction.

- high precision GTM (gantry tool movement)

- automatic printhead cleaning

- large build volume of 400x200x200mm (X,Y,Z) M(edium)

- printable upgrades

- optional engraving tool with software speed control

- CDC (cable drag chains) cable protection

other features:

- stand alone printing

- moveable, due to its rigid design

- prints small and large detailed objects

- prints rigid construction elements

- high speed printing

http://reprap.org/wiki/Cartesio

Project homepage:

http://www.mauk.cc/

Cartesio wiki and building instructions:

http://www.mauk.cc/service.html

You can alos find them on Thingivers under:

http://www.thingiverse.com/jos/designs

http://www.thingiverse.com/thing:21664

|

| CartesioW and smaller CartesioM comparison |

↧

↧

Spherebot - 3d printable xmas balls robot plotter

Christmas is coming you dusted off your xmas tree and decorated it: everybody try to make it different, buying new decorations and balls of different colors. Well, if you are looking for something original, think of making your personalized balls with drawings and writings at will.

Here comes this machine: a printer, or better to say a plotter, which will draw with a marker on spheres at will, derived from models transformed into G-code files. The machine is easily doable with a few 3D printable pieces

You can build it yourself:

.stl files at:

http://www.thingiverse.com/thing:201052

Detailed build instructions and code:

http://www.open-electronics.org/spherebot-reloaded-customize-your-xmas/

Marry Xmas people!!!! HO HO HO!

↧

Fusematic 3d printer

From Fusematic page:

Meet the next generation of Maker’s Tool Works 3D printers. The Fusematic 3D printer is smaller, faster, and more affordable than the MendelMax 2, but made with the same commitment to quality that you have come to expect from MTW.

The Fusematic 3D printer was designed from the ground up for simplicity and reliability. A low part count, linear rails on all axes, and high-reliability electronics are just a few of the elements that set the Fusematic apart. And the electronics are all fully enclosed inside the base, making the Fusematic an excellent choice for schools and office environments.

Faster, Easier Assembly

The machined case with integrated assembly guides makes alignment easy.

Linear rails on all axes.

Preassembled print controller with a pre-configured downloadable firmware for nearly plug-and-play electronics

Keyed connectors prevent the most common electronic problems like shorts and assembly errors, and integrated fuses prevent serious damage in the event something still goes wrong.

Improved Design

The Fusematic 3D printer’s electronics are fully enclosed, which greatly reduces the possibility of injury or electrical malfunction.

The Bowden-style extruder makes the Fusematic 3D printer’s carriage lighter, giving better print quality at higher speeds.

Tuning and calibration is easy and requires no special skills.

The included RAMBo control electronics have nearly foolproof assembly and legendary reliability.

Transportable

A user-added printable handle can be attached to the top plate to make it as easy as possible to transport.

The electronics are fully enclosed within the base, so there are fewer loose wires to snag during transport.

Rugged steel and aluminum construction.

Technical SpecificationsFusematic 3d printer is priced at 799 USD.

- Stylish black and silver components.

- Build area: 200 x 225 x 200 mm, 8 x 9 x 8 inches

- Full size of machine: 300 x 410 x 400 mm

- Layer height: User-selectable, 100 – 300 microns

- Print volume: 9000 cc, 576 cubic inches

- PLA only with base version. PLA, ABS, and experimental materials like nylon and polycarbonate with the optional heated bed

- Shipping weight: Approximately 22 lbs

- Made in the USA with US and imported parts.

http://www.makerstoolworks.com/fusematic-3d-printer/

↧

Geoweaver walking hexabot 3d printer

Geoweaver is hexabot walking robot made from lasercut and 3d printed parts that has glue gun extruder attached for printing on walking surface. IT IS A FREAKING WALKING SPIDER ROBOT 3D PRINTER!!!!! AND YOU CAN BUILD IT YOURSELF!!!

very cool ...

It is not highest quality of 3d print and it has some limitations, but this concept could be developed in the future. You could have several in your home that could print different furniture and recycle it every day ... or swarms printing buildings ...

Very detailed information with full build instructions and all the files:

http://www.instructables.com/id/Geoweaver-Walking-3D-Printing-Hexapod/?ALLSTEPS

From Instructables description:

Geoweaver is a student designed robot created in the Creative Architecture Machines advanced options studio at the California College of the Arts (CCA) in San Francisco, California, taught by Jason Kelly Johnson of Future Cities Lab and Michael Shiloh. The design is based on a 12-servo hexapod with a glue gun extruder attached, and is the culmination of about 60 days of research and prototyping. Although the robot's official name is Geoweaver, it also goes by many aliases: Servo Killer, Eater of Shields, Melter of Wires, and Destroyer of Regulators, among many others. It is a very difficult and delicate machine, and is not a project to be tackled for the faint of heart.

But if you do take it upon yourself to accept it's challenges, it's rewards are great: it is a six-legged, walking 3D printer. The center mechanism uses two servos to control the pendulum-like extruder head, allowing it to cover a basic XY plane (though curved to the surface of a sphere, see video above), and one servo for the extrusion gear that forces the glue-sticks through the "print head." All of this can be controlled through the software Rhino 5, with the plug-ins Grasshopper and Firefly

it was designed and made by Student Team: Jia Wu, Jeffrey M. Maeshiro, Mary H. Sek at CCA - California College of the Arts Architecture Advanced Options Studio, Prof. Jason Kelly Johnson with Michael Shiloh

↧

Fully 3d printed speaker from Cornell's Creative Machines Lab

Speaker was fully 3d printed including metal coil at Cornell's Creative Machines Lab by Apoorva, Robert MacCurdy and Hod Lipson. To make it printable, the electronic components are made with two customizable 3D printers: a special silver ink extrusion is used for the coil and a viscous blend of strontium ferrite is used for the magnet.

It's the future people. We just need to get more synergy and merging of 3d printed plastic and 3d printed electronics.

I hope that projects that could empower every maker to print similar speakers like Spoolhead wire embedding 3d printhead RepRap will be revived and improved. http://diy3dprinting.blogspot.com/2013/09/embedding-metal-wire-in-3d-printed.html

It's the future people. We just need to get more synergy and merging of 3d printed plastic and 3d printed electronics.

I hope that projects that could empower every maker to print similar speakers like Spoolhead wire embedding 3d printhead RepRap will be revived and improved. http://diy3dprinting.blogspot.com/2013/09/embedding-metal-wire-in-3d-printed.html

↧

↧

Video updates on Theta polar printer

Theta printer has unique design:

http://diy3dprinting.blogspot.com/2013/11/theta-printer-4-extruder-polar-3d.html

Here are some videos that show how the printer construction is progressing:

Simultaneous printing on Theta. The blue plastic is PLA and the yellow is ABS.

Two extruders printing on the same object at the same time.

Videos by Tyler Anderson

All files are at GitHub:

https://github.com/unlimitedbacon/Theta-Printer

Theta printer project blog:

http://csulbmae472group7.weebly.com/

http://diy3dprinting.blogspot.com/2013/11/theta-printer-4-extruder-polar-3d.html

Here are some videos that show how the printer construction is progressing:

Simultaneous printing on Theta. The blue plastic is PLA and the yellow is ABS.

Two extruders printing on the same object at the same time.

Videos by Tyler Anderson

All files are at GitHub:

https://github.com/unlimitedbacon/Theta-Printer

Theta printer project blog:

http://csulbmae472group7.weebly.com/

|

| First print results in PLA and ABS at the same time on same object |

↧

Gnublin 3D printer and pcb mill hybrid

This is a project of 3d printer and low cost PCB mill hybrid machine with user swapable printhead / mill.

Embedded projects is developing it and surveying the market need and if they should build it.

More details and market survey:

http://shop.embedded-projects.net/index.php?module=special&action=printer&lang=en

↧

New 3d printers from India: Brahma3 Anvil and Mi3D Pro X9

More printers are coming up in India. 3d printers are emerging everywhere. Go India Go!

Technical specifications of Brahma3 Anvil:

http://www.brahma3.com/

Only information in video description is available for Mi3D Pro x9 3d printer:

Source:

http://www.youtube.com/channel/UCoaFfPE1-HFS7-gEZiftrBA?feature=watch

Brahma3 Anvil

Technical specifications of Brahma3 Anvil:

- Build Volume: 240 x 240 x 240 mm

- No. of Extruders: 1

- Nozzle Diameter: 0.4 mm

- Maximum Extruder Temperature: 350°c

- Hot End: All metal hot end

- Heated Bed with a glass print surface

- Build Platform: Metal / Glass

- Aluminum frame

- Weight: < 15kg

- Dimensions (L, D, H): 380 X 400 X 500 mm

- Slicing Support: Cloud Based

- WiFi supported

- Control unit is Android powered touchscreen tablet

- Power Consumption Rating: 12V, 260W

- Price: Rs. 100,000 (USD 1,610)

http://www.brahma3.com/

Mi3D Pro X9

Only information in video description is available for Mi3D Pro x9 3d printer:

- Mi3D ProX9 for Industry Applications/Expert Designers

- INDIA's First Double Extruder Printer

- First printer to support print resume on powercut

Source:

http://www.youtube.com/channel/UCoaFfPE1-HFS7-gEZiftrBA?feature=watch

↧

Picaso 3d Designer 3d printer from Russia

New Russian 3d printer by Picaso 3d.

Technical specifications:

http://picaso-3d.ru/

Here is video by TixTri in Russian language that shows both Picaso 3d models: Builder and focuses on Designer.

Technical specifications:

- Build volume of 200 x 200 x 200mm

- Layer size of 0.05mm

- Minimum wall thickness of 0.19mm

- Standalone machine using USB or SD card gcode input

- Two nozzles sizes, 0.30 and 0.15mm

- Display panel to monitor print operations

- Enclosed heated build chamber to minimize ABS warping effects (they probably don't care about patents that big western corporations have on heated chamber technology)

- Automatic calibration of the print bed

- Russian-specific software interface

- Price: RUB 99,000, or USD 3,000.

http://picaso-3d.ru/

Here is video by TixTri in Russian language that shows both Picaso 3d models: Builder and focuses on Designer.

↧

↧

DeltaTrix 3d printer with detailed build instructions

DeltaTrix is open source delta configuration 3d printer project by Richard Tegelbeckers. It has very detailed Instructables building guide and features sturdy cnc cut wood frame with Airtripper Bowden Extruder, RepRapPro Tricolour hot end and RAMPS electronics. He will also Kickstarter it soon.

Detailed construction manual and all the files needed:

http://www.instructables.com/id/DeltaTrix-3D-Printer/?ALLSTEPS

There are some similar detailed build guides for Delta printers like this one if you are interested in building different model:

http://diy3dprinting.blogspot.com/2013/09/extensive-roctock-delta-building.html

Update:

It is on Kickstarter now:

http://www.kickstarter.com/projects/1142241325/deltatrix-3d-printer-open-source-and-fully-hackabl

Technical specifications described in Kickstarter campaign:

Detailed construction manual and all the files needed:

http://www.instructables.com/id/DeltaTrix-3D-Printer/?ALLSTEPS

|

| DeltaTrix has sturdy CNC cut full wood frame construction |

|

| DeltaTrix print results |

There are some similar detailed build guides for Delta printers like this one if you are interested in building different model:

http://diy3dprinting.blogspot.com/2013/09/extensive-roctock-delta-building.html

Update:

It is on Kickstarter now:

http://www.kickstarter.com/projects/1142241325/deltatrix-3d-printer-open-source-and-fully-hackabl

Technical specifications described in Kickstarter campaign:

The theoretical printing area is 280mm (11 inch) in diameter. As a square this works out as (almost) 200x200mm (8"x8"), which suits the used 'MK2A' heated bed. As it is also useful to be able to remove items, the gap between the uprights is just over 295mm. The maximum build height is around 280mm (11").

Main features:

- Linear delta robot layout provides a mechanically simple motion platform for moving the print head only, not the workpiece.

- Off the shelf RAMPS electronics allow for easy replacement in case things go wrong.

- Using a LCD display and SD memory card (supplied in our kits), the DeltaTrix 3D Printer can operate on it's own. It does not need to be attached to a computer.

- There are several (Open Source) options in terms of software. At the moment we are using Repetier on the PC, a modified version of Marlin as the firmware on the RAMPS electronics, and the standard Arduino IDE for tweaking the firmware.

- A heated bed with glass print surface, allows for PLA and ABS to be used as filament.

- In terms of filament, the DeltaTrix 3D Printer is designed to accept 1.75mm PLA and ABS on a variety of 1kg reels, as long as it is of good quality.

- Igus linear slides with pretension are used, providing a robust and durable bearing solution from a highly reputable manufacturer. The strengthening ribs on the uprights keep the rails straight and sturdy.

- The current design print head assembly uses a single Reprappro Hot End, with a nozzle size of 0.3 or 0.5mm. The assembly also has a fan and integrated duct for cooling the top of a print.

- Quick changeover print head assembly. Useful for swapping between two print head assemblies, eg. one for ABS and one for PLA. The prototypes use connection blocks, but the kit will have proper connectors. Please, note: the standard kit only contains parts for one off print head assembly.

↧

Custom Delta 3d printer built from Ikea furniture pieces

Turi Cacciatore made this Rostock based custom Delta 3d printer with frame made from Ikea furniture pieces. He used carbon archery arrows for delta arms. Nice work!

Source with detailed information and building guide:

http://turicacciatore.tumblr.com/post/69085105229/making-my-3d-printer

You can see another 3d printer from hacked Ikea furniture pieces, the Ikea RepRap, here:

http://diy3dprinting.blogspot.com/2013/11/diy-3d-printers-made-from-wood.html

Source with detailed information and building guide:

http://turicacciatore.tumblr.com/post/69085105229/making-my-3d-printer

|

| Custom Delta frame made from cut Ikea pieces pictured above |

You can see another 3d printer from hacked Ikea furniture pieces, the Ikea RepRap, here:

http://diy3dprinting.blogspot.com/2013/11/diy-3d-printers-made-from-wood.html

↧

Stratum Networks Delta Robot 3d printer

Stratum Networks Delta is a student project of clay printing Delta 3d printer. Design is published on Instructables and the printer is made with air compressor powered clay extruder mounted on lasercut plywood and acrylic frame.

The output clay objects look rough but the precision can probably be improved.

Project developers, Max Sanchez and Taylor Fulton, are architecture students at California College of the Arts. This project was based in a studio course called "Creative Architecture Machines" taught by Jason Kelly Johnson and Michael Shiloh.

Detailed build guide and all the files needed can be found at:

http://www.instructables.com/id/Stratum-Networks-Delta-Robot/?ALLSTEPS

Here you can find detailed video from more precise ceramic clay delta printer:

http://diy3dprinting.blogspot.com/2013/06/delta-ceramic-printer-by-jonathan-keep.html

http://diy3dprinting.blogspot.com/2013/11/operating-ceramic-delta-printer-video.html

The output clay objects look rough but the precision can probably be improved.

Project developers, Max Sanchez and Taylor Fulton, are architecture students at California College of the Arts. This project was based in a studio course called "Creative Architecture Machines" taught by Jason Kelly Johnson and Michael Shiloh.

Detailed build guide and all the files needed can be found at:

http://www.instructables.com/id/Stratum-Networks-Delta-Robot/?ALLSTEPS

|

| Schematics of air compressor driven clay extruder |

Here you can find detailed video from more precise ceramic clay delta printer:

http://diy3dprinting.blogspot.com/2013/06/delta-ceramic-printer-by-jonathan-keep.html

http://diy3dprinting.blogspot.com/2013/11/operating-ceramic-delta-printer-video.html

↧