Wally is the master of corporate subtle and stealth sabotage ...

Previous Dilbert comic:

http://diy3dprinting.blogspot.com/2012/11/3d-printing-featured-in-dilbert.html

Source: http://dilbert.com/fast/2012-11-05/

|

| Project includes various types of printable hinges that hold cut foam pieces |

|

| Parts printed inside the heated enclosure on the left, and ABS part printed without heated chamber on the right with warping. |

|

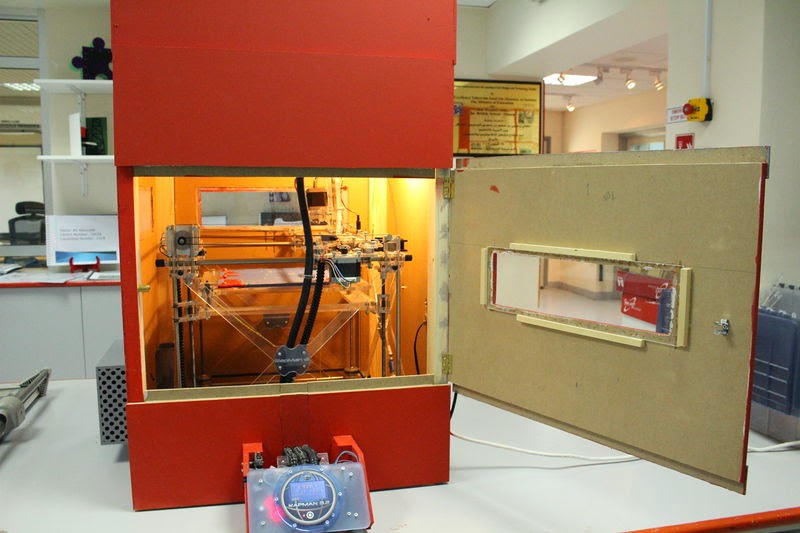

| The enclosure with printer inside it |

|

| Lasercut thermal vents. They can be done with simple hand tools also |

|

| Heater made from simple hair dryer |

| More advanced version of the enclosure with fumes extractor |

In october 2013, a famous design school in Paris, ENSCI les Ateliers, hosted a workshop organised by the French Ministry of culture. The idea was to use images, videos and sound fallen in the national pubic domain and use them in a sort of “Mashup”. The event was called Public Domain Remix.

The students had one day (8 hours) to pick their digital material and transform it, hack it or remix it.

Le FabShop, was invited as a digital manufacturing expert to help the students realise their project.

After a short brainstorm, all the teams came up with similar ideas, except one, who really went out of the box with their concept. They had this silly idea of making a machine that could automatically create tattoos taken from a bank of images. They learned from le FabShop's representative that their concept was more than feasible. It could be prototyped by themselve, using the school's equipment.

In one afternoon, they managed to hack a Desktop 3D printer and enable it to trace on skin, using a pen instead of the extruder. The crowd was amazed and the Minister of culture even came to see the projects, but the young designers didn’t want to stop there. They wanted the machine to make REAL tattoos, on REAL skin, so they kept working on the project during their spare time, with some help from teachers and other students.

They borrowed a manual tattoo-machine from an amateur tattoo artist and found some artificial skin for the first tests. They chose to draw a simple circle. The perfect shape to test the precision of the process. It worked! But now they had to find a volunteer to be their “guiney pig”…

Somehow, they had no difficulty. A lot of people where excited by the idea of being the first human tatooed by a “robot”.

The big difficulty was to repeat the same exercise on a curve surface and on a material that has much more flexibility than silicone. Many tricks were tried to tighten the area around the skin ( a metal ring, elastics, scotch tape...) but the most effective one was a scooter’s inner tube, open on the area to be marked.

|

| Max and Christina of Wikifactory |

|

| April fools day |

| Dans DLP resin printer |

| DLP projector and mirror |

|

| AR15 rifle rail printed on this machine with graphite powder added into resin |

The T-Bone is a cape for the BeagleBone Black, dedicated for motion control. These are 3D printers, laser cutters, milling machines, and other applications using stepper motors.

The T-Bone will come preprogrammed for Reprap Mendel 3D Printer. Best kown in the Prusa Mendel or Prusa i3 variant. The Software will include low level drivers, the printer application and a high level Web Interface for control. Just connect your steppers, heaters and sensors, configure the software and you are ready to print.

To join highest performance with flexibility and easy programming, we use a very powerful concept: Hard- and software abstraction layers! User interface, configuration, G-Code interpreter, and path planner are running on the BeagleBone. This makes it easy to use existing open source software components, using the existing toolchain on the Linux operating systems of the BeagleBone. Real-time communication with the BeagleBone is handled by a small microcontroller, placed on the T-Bone. The microcontroller is fully compatible with the Arduino toolchain, so everybody can easily modify it. Complex acceleration and velocity calculations for the stepper motors are done by dedicated motion controllers. These are dedicated hardware components, developed to get the maximum performance out of a given stepper motor without putting any workload to the host system.

The low level drivers for the motion controllers and realtime applications are written with the Arduino IDE in C. The higher level applications for G-Code analysis, motion control and web interface are written in Python. There are no special hardware drivers involved. Most of the hardware can be used on the built in Arduino or BeagleBone Black. All software will be released as open source software on github.

Here are the main features of the basic board:

- 5 stepper motor driver (run syncronized, 3 x up to 4 A, 2 x up to 1.5 A)

- 10 inputs for end switches (two for each axis)

- 3 inputs for incremental encoders (3 axis supporting closed loop control)

- 3 inputs for thermistors

- 1-wire interface for digital temp and other sensors

- 2 high power outputs (for extruder and heatbed, up to 12 A)

- 1 mid power output (for fans, LEDs, ..., also expandable)

- Power supply for BeagleBone (5 V, 1.2A)

- Input voltage 12 - 24 V

- For more detailed description of the hardware features see here (to be continued...).

But that's not all. We are planning to create some additional expansion boards with special features. Here are some of the feature we are planning:

- Support for rotary axis like driller, miller, ...

- Support for laser cutters

- External touch panel display

- Support for other hardware platforms

And you can do even more! The software is easily adaptable to most CNC applications. If you want to connect your CNC mill you do not have to develop it from ground up, just adapt the printing logic a bit.

|

| QuadRap in first version |