|

| Arup developed 3d printed steel part |

|

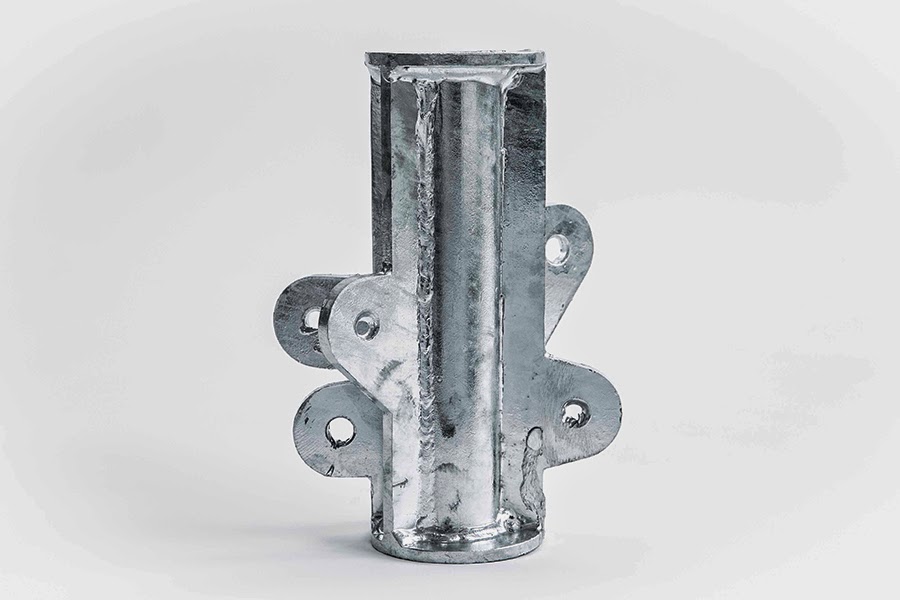

| Traditional steel element of same purpose |

From the source:

Using the latest 3D printing techniques, or more accurately, ‘additive manufacturing’ – the Arup team has produced a design method for critical structural steel elements for use in complex projects.

The work signals a whole new direction for the use of additive manufacturing in the field of construction and engineering. The research also shows that additive manufacturing has the potential to reduce costs, cut waste and slash the carbon footprint of the construction sector.

We created a redesign of a steel node for a light weight structure using additive manufacturing. Arup has a lot of experience with these kind of structures, for example the tensegrity structure of the Kurilpa Bridge in Australia. The complex geometry of these kind of nodes are an ideal showcase of the possibilities of this new technique.

"By using additive manufacturing we can create lots of complex individually designed pieces far more efficiently. This has tremendous implications for reducing costs and cutting waste. But most importantly, this approach potentially enables a very sophisticated design, without the need to simplify the design in a later stage to lower costs.”– Salomé Galjaard, Team Leader, Arup

A traditionally produced steel node is at the moment still cheaper to produce, but it is expected that this will change in the short term.

Source:

http://www.arup.com/News/2014_06_June/05_June_Construction_steelwork_makes_3D_printing_premiere.aspx

If you have some doubts and want to see more about high strength optimized 3d printed structures, take a look at:

http://diy3dprinting.blogspot.com/2012/11/fractal-3d-printing-for-ultra-high.html