Andreas Bastian made this guide for sand blasting 3d printed PLA objects to give matte surface finish with reduced visible layering and shiny parts.

His conclusions were:

Source with more details and results photos:

http://www.instructables.com/id/3D-Print-Finishing-Technique-for-Improved-Surface-/?ALLSTEPS

Andreas is also well known for his work on e-Nable and Open SLS 3d printer.

If you are more interested in surface finish and smoothing of 3d printed objects with acetone look at:

http://diy3dprinting.blogspot.com/2013/06/smoothing-and-polishing-pla-with-thf.html

http://diy3dprinting.blogspot.com/2013/03/more-on-acetone-vapor-smoothing.html

http://diy3dprinting.blogspot.com/2013/03/smoothing-models-with-acetone-vapor-bath.html

His conclusions were:

- Even blasting helps the final surface quality.

- Additional shells (3 or 4) help keep the print sealed during washing.

- After blasting, the matte surface is prone to absorbing skin oils and other particles, much the way an SLS print does.

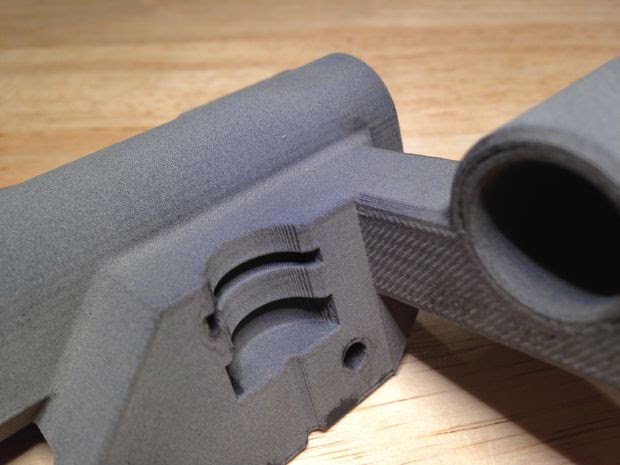

- The blasting grit will alter the color of lighter PLAs, the white took on more of a bone hue and the natural clear developed a somewhat murky color. The black PLA blasted to a very nice matte grey.

|

| White PLA object inside sand blaster |

|

| Close-up of sand blasted black PLA object |

|

| Non-sand blasted compared to sand-blasted PLA |

Source with more details and results photos:

http://www.instructables.com/id/3D-Print-Finishing-Technique-for-Improved-Surface-/?ALLSTEPS

Andreas is also well known for his work on e-Nable and Open SLS 3d printer.

If you are more interested in surface finish and smoothing of 3d printed objects with acetone look at:

http://diy3dprinting.blogspot.com/2013/06/smoothing-and-polishing-pla-with-thf.html

http://diy3dprinting.blogspot.com/2013/03/more-on-acetone-vapor-smoothing.html

http://diy3dprinting.blogspot.com/2013/03/smoothing-models-with-acetone-vapor-bath.html